Crush Strength

Mechanical Behavior of Gaskets

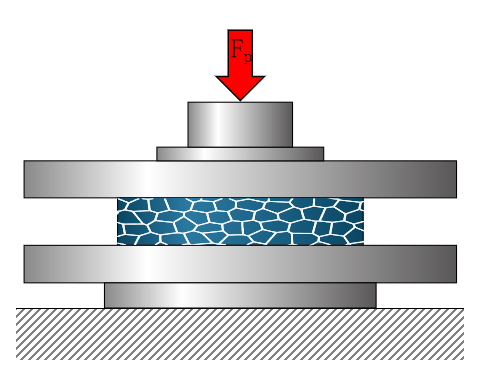

In industrial sealing systems, the sealing effect of a gasket is closely related to stress. Theoretically, the higher the gasket stress, the less the leakage. However, if the stress exceeds the limit, the gasket will be crushed or fragmented. The ultimate load (or the corresponding stress) that causes the gasket to crush is the crush strength.

Crush Strength

The test method for crush strength has clear standards. Unlike the "setting of target load" in the test of compression resilience, no load is preset when testing crush strength. Instead, a dedicated device is used for continuous loading, with the load increased slowly and continuously, and the changes in load are recorded simultaneously.

When there is a sudden drop or an obvious inflection point in the load, it indicates that the gasket structure has been damaged (such as internal fiber breakage, matrix fragmentation). The load (Fp) or stress (σp) at this time is the crush strength of the gasket.

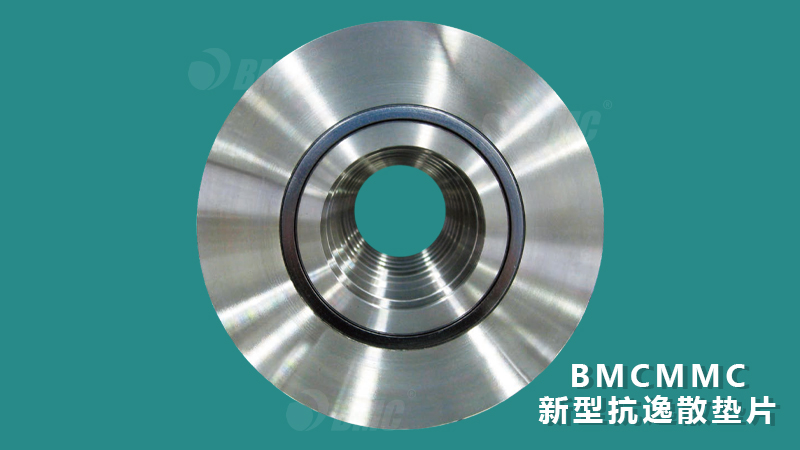

BMCMMC: High-Temperature and High-Pressure Resistant High-Performance Sealing Gasket for Petrochemical Industry

Why must we pay attention to the crush strength of sealing gaskets? In practical applications, if a gasket is crushed, it will not only lose its sealing ability and cause medium leakage, but also may adhere to the flange surface, increasing maintenance costs.

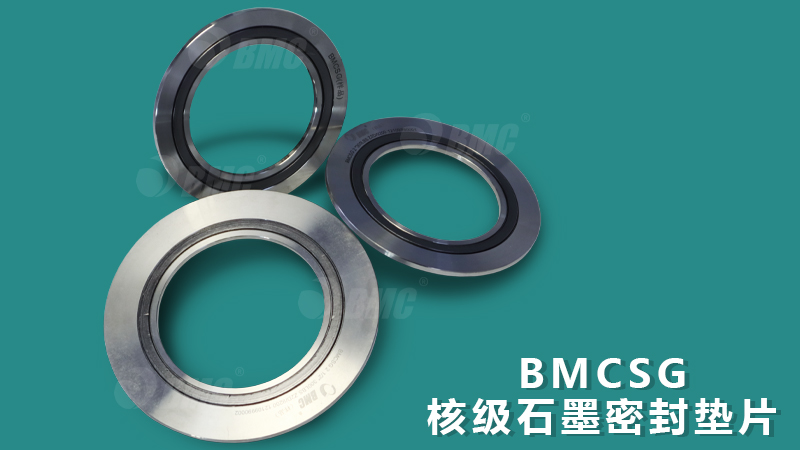

BMCSG: Realizing Constant Sealing Stress for Harsh Operating Conditions

Only by clarifying the crush strength can we strike a balance between "ensuring sealing" and "avoiding crushing", which is also an important prerequisite for subsequent gasket selection and installation.

Ingenious Seal Mastery

For sealing leakage issues, Baohua provides solutions. If you have any doubts about sealing technology, please pay attention to Suzhou Baohua and feel free to consult, comment, or leave a message! Thank you all! We will continue to talk about crush strength in the next issue, see you next time!

Email:[email protected]

Email:[email protected]